Discover the essential steps and key considerations involved in constructing a functional and durable cattle shed that meets the needs of your livestock while ensuring efficiency and safety. Building a cattle shed requires careful planning, appropriate material selection, and attention to environmental factors to promote animal health and productivity.

This guide covers everything from designing the layout and choosing sustainable materials to installing proper ventilation, lighting, water systems, and security features, providing you with comprehensive knowledge to undertake this valuable project successfully.

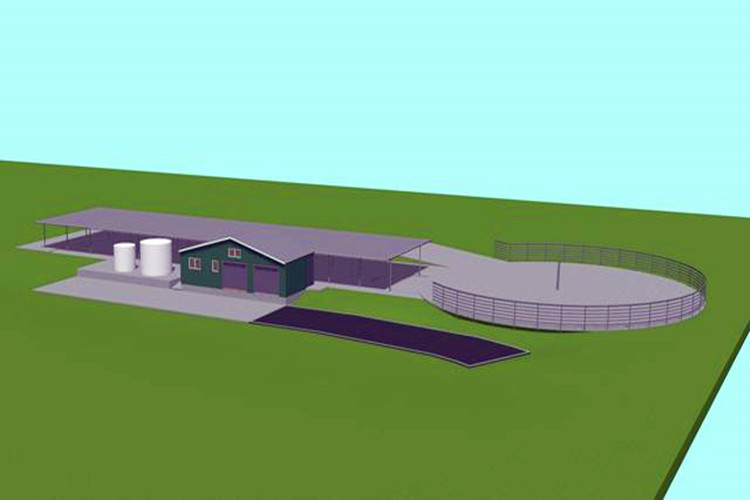

Planning and Design of a Cattle Shed

Effective planning and thoughtful design are fundamental to establishing a cattle shed that ensures the health, comfort, and productivity of livestock. Properly designed structures can mitigate environmental stressors, optimize space utilization, and promote efficient management practices. Tailoring the shed’s layout and features to specific climate conditions and herd requirements plays a critical role in long-term success.

Designing a cattle shed involves evaluating various factors such as climate, herd size, available space, and resource accessibility. An ideal design incorporates natural ventilation and lighting strategies to maintain optimal environmental conditions, reduce dependence on artificial systems, and lower operational costs. This section guides you through essential considerations and practical steps necessary for creating a functional and sustainable cattle shelter.

Considerations for Climate-Adapted Design

Climate significantly influences the structural features and materials used in cattle shed construction. For hot and humid regions, the focus is on maximizing ventilation and providing shade to prevent heat stress. In colder climates, insulation and proper heating options are crucial to sustain cattle comfort. Similarly, in rainy areas, adequate drainage and waterproofing are essential to maintain dry and clean environments.

In designing for varying climates, the following considerations are vital:

- Ventilation: Ensure sufficient airflow to remove excess heat, moisture, and harmful gases. Incorporate adjustable sidewalls, ventilators, and ridge openings.

- Shade and Shelter: Use roofing and wall materials that reflect heat and provide protection from direct sunlight or rain.

- Materials: Select durable, climate-appropriate materials that withstand local weather conditions and require minimal maintenance.

- Drainage: Design proper channels and slopes to prevent water accumulation and promote quick runoff during heavy rains.

Determining Size and Capacity

Allocating adequate space for each animal is critical to ensure comfort, reduce stress, and promote proper health management. The size of the cattle shed should be proportional to herd size, considering future growth and operational convenience.

Steps to determine appropriate dimensions include:

- Identify herd size: Count the total number of cattle to be housed, including calves, adult cows, and bulls.

- Calculate space requirements per animal: Typically, a minimum of 3-4 square meters per adult cow in a free-stall system, and 1-2 square meters in a loose-housing arrangement. Calves need approximately 1-1.5 square meters each.

- Plan for extra space: Add 10-15% to accommodate future herd growth or additional equipment.

- Determine shed dimensions: Multiply the space requirement per animal by the herd size, then divide into the available layout options.

For example, for a herd of 20 adult cows, allocating 4 square meters per cow results in a total of 80 square meters of space. Incorporating aisles, feeding areas, and walkways can increase the overall size by 25-30%.

Layout Options with Dimensions and Features

Organizing the cattle shed layout effectively enhances animal welfare and simplifies management. Below is a responsive table presenting common layout options, including dimensions, space allocations, and key features that adapt to various herd sizes and operational needs.

| Layout Type | Approximate Dimensions | Space per Animal | Main Features |

|---|---|---|---|

| Single-Row Shed | 20m x 10m (200 sq.m) | 3-4 sq.m for adults, 1-1.5 sq.m for calves | Animals housed in a single row with feeding and watering points on one side; suitable for small herds. |

| Double-Row Shed | 30m x 12m (360 sq.m) | 4 sq.m per adult; wider aisles for ease of movement | Animals housed on both sides with central alley; facilitates efficient cleaning and management. |

| Lofted or Multi-Level Shed | Varies based on design; typically 25m x 15m | Enhanced space utilization, with separate resting and feeding zones | Provides natural insulation and ventilation; ideal for regions with limited land area. |

These layout options can be customized to meet specific herd requirements, available land, and operational preferences. The selection should prioritize animal comfort, ease of access, and maintenance efficiency.

Incorporating Natural Ventilation and Lighting

Natural ventilation and lighting are cost-effective, environmentally friendly, and contribute significantly to maintaining a healthy and stress-free environment for cattle. Proper integration of these elements reduces dependency on mechanical systems, lowering energy costs and promoting sustainability.

Strategies for effective natural ventilation include:

- Ridge Ventilation: Installing ventilators along the roof ridge allows hot air to escape, creating a continuous airflow.

- Sidewall Openings: Adjustable side curtains or windows enable control over airflow, especially during different weather conditions.

- Ventilated Sidewalls: Using louvered or perforated sidewalls enhances cross-ventilation, facilitating fresh air circulation throughout the shed.

For natural lighting, consider the following approaches:

- Strategic Window Placement: Position windows on opposite sides to promote cross-lighting, reducing dark corners and shadows.

- Skylights: Incorporate translucent roofing panels or skylights to maximize daylight penetration, especially in larger sheds.

- Openings and Vents: Ensure openings are screened to prevent entry of pests and debris, while allowing adequate light and air.

Descriptive design elements include large, operable side openings covered with insect-proof screens, high-set ridge vents for hot air escape, and skylights made of durable, UV-resistant material that diffuse natural light evenly across the space. These features contribute to a cooler, brighter, and healthier environment for the cattle, ultimately supporting better productivity and welfare.

Materials and Construction Methods

Building a durable, cost-effective cattle shed requires a careful selection of materials and construction techniques that balance longevity, affordability, and practicality. Choosing appropriate materials not only ensures the safety and comfort of the cattle but also influences maintenance costs and the overall lifespan of the structure. Additionally, employing suitable construction methods can optimize resource use and enhance structural integrity, contributing to a sustainable and efficient livestock shelter.The selection of construction methods and materials hinges on factors such as climate, local availability, budget constraints, and environmental impact.

Understanding the strengths and limitations of each approach allows for informed decision-making, resulting in a cattle shed that serves its purpose effectively over many years.

Materials for Building Cattle Sheds

The materials used in constructing cattle sheds should emphasize durability, ease of maintenance, cost-efficiency, and environmental sustainability. Popular choices include wood, metal, and brick, each with distinct advantages and considerations.

- Wood: Widely used for its availability and ease of construction, wood provides good insulation and a natural environment for cattle. However, it is susceptible to pests, decay, and requires regular maintenance. Treated or hardwood variants can extend lifespan but may increase costs.

- Metal Panels: Made primarily from galvanized steel or aluminum, metal panels are highly durable, weather-resistant, and quick to install. They are ideal for roofing and walling, offering longevity with minimal maintenance, though they may conduct heat and cold, affecting animal comfort if not properly insulated.

- Brick Masonry: Brick structures are extremely durable, fire-resistant, and low-maintenance. They provide excellent thermal mass, maintaining stable internal temperatures. The initial cost is higher, and construction time is longer compared to other options, but the durability compensates over the long term.

Comparison of Construction Methods

Different construction methods influence the durability, cost, and ease of assembly for cattle sheds. Below is a comparison table highlighting the key features of common approaches.

| Construction Method | Pros | Cons | Suitability |

|---|---|---|---|

| Wood Framing |

|

|

Ideal for small-scale or temporary structures, or in regions with abundant timber. |

| Metal Panels |

|

|

Suitable for large-scale, durable structures requiring minimal upkeep. |

| Brick Masonry |

|

|

Best for permanent, large-scale cattle sheds prioritizing longevity and thermal regulation. |

Tools and Equipment for Construction

Efficient construction relies on proper tools and equipment, ensuring safety and precision during the building process. The essential tools include:

- Measuring tape and leveling instruments: For accurate measurements and ensuring the structure is level, which is critical for stability and functionality.

- Hammer and nails or screwdrivers and screws: Basic tools for assembling wooden frameworks or attaching panels.

- Power saws (circular or chainsaw): For cutting wood or metal sheets to size with precision.

- Drill machine: Facilitates quick installation of fasteners and holes for fittings.

- Concrete mixers and shovels: Used when constructing foundations or footings with concrete.

- Lifting equipment (hoists, pulleys, or cranes): For handling heavy materials such as bricks or steel panels safely.

- Protective gear (helmets, gloves, masks): Ensures safety during construction activities.

Sustainable Building Practices

Implementing environmentally responsible building practices enhances the sustainability of cattle sheds, reduces long-term costs, and minimizes ecological impact.

- Utilizing locally available materials reduces transportation emissions and supports regional economies. For example, using locally sourced timber or bricks minimizes environmental footprint.

- Incorporating renewable energy sources, such as solar panels, can power lighting and ventilation systems, decreasing reliance on non-renewable energy.

- Designing for natural ventilation and daylight reduces energy consumption for cooling, heating, and lighting.

- Employing rainwater harvesting systems can supply water for cleaning and other non-potable uses, reducing water dependency.

- Using eco-friendly coatings and treatments on wood and other materials ensures minimal chemical runoff and safer environments for animals and humans.

- Designing modular and expandable structures allows for future modifications with minimal resource wastage.

Foundations and Flooring

Establishing a solid and hygienic foundation is essential for the durability and functionality of a cattle shed. The proper selection and construction of foundations and flooring not only provide stability but also contribute significantly to the health and comfort of the livestock. An appropriately designed foundation prevents settling, reduces maintenance costs, and ensures the longevity of the structure, while the right flooring type facilitates cleaning, minimizes injuries, and promotes hygiene.

Careful planning and execution of foundation and flooring work are critical components in the overall construction process. They require consideration of factors such as soil type, climate conditions, cattle behavior, and operational needs, ensuring the shed remains practical, safe, and sustainable over years of use.

Types of Foundations for Cattle Sheds

Different foundation types are suitable for cattle sheds depending on soil characteristics, load-bearing requirements, and local environmental conditions. Selecting the appropriate foundation enhances structural stability and minimizes potential issues like uneven settling or water infiltration.

- Strip Foundation: A continuous footing that runs beneath load-bearing walls, providing uniform support. Ideal for sheds on firm, stable soils and where the structure is relatively lightweight. Benefits include ease of construction and good load distribution.

- Pad (Column) Foundation: Isolated footings supporting individual columns or posts, suitable for sheds with post-and-beam structures. It minimizes material use and is effective on stable soils.

- Raft (Mat) Foundation: A thick reinforced concrete slab that covers the entire shed area, distributing loads evenly. Ideal for soft or unstable soils where other foundation types might settle unevenly. It offers excellent stability but is more costly.

- Pier Foundation: Use of concrete or stone piers spaced at intervals, elevating the structure above the ground. Suitable for sheds in flood-prone areas or uneven terrain, providing good drainage and ventilation benefits.

Procedures for Laying Concrete or Other Foundations

Ensuring the proper laying of foundation materials is fundamental for structural integrity. The process involves meticulous steps that guarantee strength and durability.

- Site Preparation: Clear the area of vegetation, debris, and loose soil. Level the ground and define the boundary lines based on the shed design.

- Excavation: Dig trenches or pits according to the foundation type, ensuring the depth and width meet engineering specifications. The depth should extend below the frost line in colder regions to prevent freezing damage.

- Formwork Construction: Erect formwork using timber or metal to shape the concrete, ensuring proper dimensions and levelness. Secure the forms firmly to withstand the concrete pour.

- Reinforcement Placement: Install steel reinforcement bars (rebars) within the forms, following structural design guidelines. Proper spacing and positioning are crucial for load-bearing capacity.

- Pouring Concrete: Mix concrete to the specified ratio, ensuring consistency and workability. Pour the concrete slowly to avoid air pockets, starting from one end and filling the form uniformly.

- Finishing and Curing: Level the surface with tools like trowels, and smooth the top. Cover the foundation with damp cloths or plastic sheets to retain moisture, facilitating proper curing for at least seven days.

- Removal of Formwork: Carefully dismantle the forms after the concrete has gained sufficient strength, typically after 24-48 hours, and continue curing as needed.

Flooring Options for Cattle Sheds

The choice of flooring impacts animal comfort, hygiene, and ease of maintenance. Below is a table illustrating common flooring options, highlighting their advantages to aid in selecting the most suitable type for specific needs.

| Flooring Type | Advantages |

|---|---|

| Concrete Flooring |

|

| Gravel Flooring |

|

| Rubber Mats |

|

Best Practices for Maintaining Clean and Hygienic Flooring

Maintaining a clean and hygienic floor is vital for preventing disease and ensuring the health and productivity of cattle. Implementing effective practices reduces manure accumulation, minimizes odors, and promotes a healthy environment.

- Implement a regular cleaning schedule, including removing manure and soiled bedding daily or as needed.

- Ensure proper drainage systems are in place to prevent water pooling and mud formation.

- Use disinfectants periodically to sanitize the floor, especially after cleaning.

- Inspect flooring surfaces regularly for damage or wear, repairing cracks or holes promptly to prevent injury and contamination.

- Utilize appropriate bedding materials, such as straw or sawdust, to absorb moisture and facilitate easier cleaning.

- Maintain proper ventilation to reduce humidity and odor buildup, promoting a healthier environment for the cattle.

Roofing Systems

The roofing system of a cattle shed plays a crucial role in protecting livestock from harsh weather conditions, maintaining optimal temperature, and ensuring longevity of the structure. Selecting the appropriate roofing material and design is essential for creating a durable, weather-resistant, and comfortable environment for cattle.

Various roofing options are available, each with unique advantages and suitability depending on local climate, budget, and aesthetic preferences. Proper installation and design considerations, including insulation, drainage, and ventilation, significantly influence the overall effectiveness of the roofing system in safeguarding cattle and enhancing shed durability.

Types of Roofing Materials and Their Suitability

Choosing the right roofing material involves assessing factors such as durability, cost, ease of installation, weather resistance, and maintenance requirements. Common roofing options include metal sheets, tiles, and thatch, each serving different needs and environments.

- Metal Sheets: Typically made of galvanized steel or aluminum, metal sheets are highly durable, lightweight, and easy to install. They offer excellent weather resistance, are resistant to pests, and require minimal maintenance. Metal roofs are suitable for regions with heavy rainfall, snow, or high wind conditions, providing long-term protection and energy efficiency when paired with insulation.

- Tiles: Clay or concrete tiles provide a traditional aesthetic, strong weather resistance, and thermal insulation properties. They are highly durable and can last several decades if properly maintained. Tiles are suitable for moderate to warm climates and are often used in areas where aesthetic appeal is important.

- Thatch: Made from natural materials such as straw, palm leaves, or grass, thatch provides good insulation and a rustic look. It is lightweight and inexpensive but requires regular maintenance and is less durable compared to metal or tile options. Thatch is suitable for small-scale or traditional cattle sheds in regions with abundant natural materials.

Roof Installation Process, Durability, and Weather Resistance

The installation of a roof must prioritize durability and resistance to local weather conditions. A systematic approach ensures the roof withstands environmental stresses, minimizes maintenance, and prolongs service life.

- Preparation: Inspect and prepare the supporting structure, ensuring it is strong and level to support the roofing material securely.

- Laying the Underlayment: Install a weather-resistant underlayment, such as a waterproof membrane or tar paper, to provide an additional barrier against moisture and leaks.

- Installation of Roofing Sheets or Tiles: Secure roofing materials, starting from the lower edge and progressing upward. Use appropriate fasteners, such as screws with rubber washers for metal sheets, to prevent leaks and wind damage.

- Sealing and Finishing: Ensure all overlaps and joints are adequately sealed, especially in corners and edges, to prevent water ingress and enhance weather resistance.

Durability depends on proper fastening, sufficient overlap, and high-quality materials. Regular maintenance, such as inspecting for loose fasteners, rust, or damage, extends the lifespan of the roofing system. Additionally, using corrosion-resistant fasteners and reflective coatings can improve weather resistance and energy efficiency.

Insulation Techniques for Temperature Regulation

Effective insulation in the roofing system helps regulate internal temperatures, protecting cattle from extreme heat and cold, thereby promoting health and productivity. Several insulation techniques can be employed to enhance thermal comfort:

- Installing Insulation Panels: Rigid foam or mineral wool panels placed beneath the roofing material provide high thermal resistance and are easy to install during construction.

- Using Reflective Coatings: Applying reflective paint or coatings on the roof surface reduces heat absorption, especially beneficial in hot climates.

- Adding Ventilated Attics or Air Gaps: Creating an air cavity between the roofing material and insulation layer enhances airflow, reducing heat buildup and moisture accumulation.

- Incorporating Green Roofs: Installing vegetative layers on the roof can provide natural insulation, reduce temperature fluctuations, and improve overall environmental conditions.

Ensuring Proper Drainage and Ventilation

Designing the roofing system with adequate drainage and ventilation is vital for preventing water accumulation, reducing moisture-related issues, and maintaining a healthy environment inside the cattle shed. Proper drainage directs rainwater away from the structure, while ventilation ensures airflow that reduces humidity and heat buildup.

- Roof Slope: Incorporate an appropriate pitch to facilitate water runoff. Steeper slopes prevent water pooling and reduce leakage risks.

- Gutters and Downspouts: Install gutters along the eaves and connect downspouts to channel rainwater away from the foundation, preventing water damage and soil erosion.

- Vents and Ridge Openings: Place vents at eaves, ridges, or gables to enable continuous airflow, reducing heat and moisture accumulation within the shed.

- Design for Cross-Ventilation: Ensure open spaces or adjustable vents on opposite sides of the shed to promote effective cross-ventilation, which helps maintain a comfortable temperature and reduces ammonia build-up.

Regular cleaning of drainage systems and maintenance of vents are essential for optimal performance. Properly designed roofing systems that integrate drainage and ventilation contribute significantly to the longevity of the structure and the health of the cattle.

Ventilation and Lighting Solutions

Effective ventilation and lighting are vital components in the design of a cattle shed, directly impacting the health, comfort, and productivity of the livestock. Proper airflow reduces humidity and the buildup of harmful gases such as ammonia, while adequate lighting ensures cattle remain healthy and exhibit natural behaviors. Incorporating suitable ventilation systems and lighting arrangements creates an optimal environment that promotes animal well-being and operational efficiency.Good ventilation systems facilitate continuous air exchange, helping to remove excess moisture, heat, and airborne contaminants.

Proper lighting, whether natural or artificial, supports circadian rhythms and enhances animal comfort. Achieving a balance between the two is essential to maintain a healthy, stress-free environment for cattle.

Ventilation Systems for Cattle Sheds

The selection of ventilation systems depends on the shed size, local climate, and economic considerations. The main types of ventilation include natural, mechanical, and mixed systems, each offering specific advantages.

- Natural Ventilation: Utilizes wind and thermal buoyancy to promote airflow through strategically placed openings such as windows, vents, and ridges. It is cost-effective and environmentally friendly, especially suitable for moderate climates. Proper placement of openings on opposite sides of the shed encourages cross-ventilation, which effectively removes stale air and maintains a fresh environment.

- Mechanical Ventilation: Involves the use of exhaust fans, ceiling fans, or duct systems to actively circulate air. Exhaust fans are typically installed at high points to expel warm, humid air, while intake vents allow fresh air to enter. Mechanical systems are beneficial in areas with insufficient natural airflow or during extreme weather conditions when natural ventilation is inadequate.

- Mixed Ventilation: Combines natural and mechanical methods to optimize airflow, reducing energy costs while maintaining adequate ventilation. For instance, natural ventilation can be supplemented with exhaust fans during hot seasons or when wind conditions are unfavorable.

Installation of Windows, Vents, and Exhaust Fans

Strategic placement and proper sizing of openings and mechanical devices are crucial for effective ventilation. Windows should be positioned on opposite sides of the shed to facilitate cross-ventilation, with sizes proportional to the shed dimensions; generally, openings should constitute approximately 10-15% of the wall area. Vents can be installed at the eaves or ridge to allow warm air to escape naturally.

Exhaust fans should be installed at the highest points of the shed to expel hot, moist air efficiently, with capacities matched to the shed volume and expected load.Key considerations include:

- Ensuring all openings are protected with screens to prevent entry of pests and debris.

- Using adjustable vents to control airflow according to seasonal needs.

- Incorporating automatic exhaust fans with humidity and temperature sensors for optimal performance.

- Designing openings to minimize drafts directly hitting the cattle to prevent stress and health issues.

Lighting Practices in Cattle Sheds

Lighting significantly influences cattle behavior, health, and milk production. Proper lighting strategies involve balancing natural and artificial sources to ensure adequate illumination throughout the day while minimizing stress and maintaining circadian rhythms. A well-lit environment encourages natural grazing behaviors and reduces the incidence of injuries or health problems related to poor visibility.

| Lighting Option | Advantages | Disadvantages |

|---|---|---|

| Natural Lighting |

|

|

| Artificial Lighting |

|

|

Tips for Optimizing Light Placement for Cattle Comfort and Health

Ensuring proper light placement involves strategic planning to promote healthy behaviors and prevent stress. Light fixtures should be positioned to distribute illumination evenly across the shed, avoiding dark corners or overly bright spots that can cause discomfort. The height of light fixtures must be adequate—typically 3-4 meters above the ground—to prevent direct glare into the cattle’s eyes.State-of-the-art lighting systems incorporate adjustable brightness levels, enabling management to adapt to different times of day or seasons.

Utilizing diffused or indirect lighting helps minimize shadows and glare, creating a calm environment. For natural lighting, large, well-placed windows with transparent or translucent coverings should be installed to maximize daylight while preventing excessive heat gain. It is advisable to align windows with the cattle’s natural activity zones and ensure unobstructed access to daylight.Proper light management not only enhances cattle comfort and health but also improves operational safety and efficiency within the shed environment.

Water Supply and Drainage Systems

Establishing an efficient water supply and drainage system is essential for maintaining healthy and productive cattle. Properly designed systems ensure animals have access to clean water and prevent waterlogging that can compromise the structural integrity of the shed and promote disease development. Reliable water delivery and effective drainage contribute significantly to the overall hygiene and operational efficiency of a cattle shed.

Integrating these systems requires careful planning to meet the daily water needs of the cattle while ensuring environmental sanitation. This involves selecting appropriate water sources, designing suitable distribution mechanisms, and implementing drainage solutions that handle waste water and excess rainwater effectively. Proper maintenance and water quality management are also critical to safeguard animal health and reduce disease risks.

Methods for Installing Reliable Water Supply Systems

Reliable water supply systems in cattle sheds typically consist of water sources, distribution networks, and delivery points such as troughs and automatic waterers. Ensuring a consistent and clean water supply involves several steps:

- Source Selection: Identify safe, sufficient water sources, such as boreholes, wells, or municipal supplies, ensuring water is free from contaminants.

- Piping and Distribution: Use durable materials like PVC or HDPE pipes for underground or overhead distribution, minimizing leakage and contamination risks.

- Water Delivery Devices: Install troughs made from stainless steel or durable polyethylene. Automatic waterers equipped with float valves can provide continuous access, reducing manual labor and ensuring water availability at all times.

- Filtration and Treatment: Incorporate filters and chlorination units as needed to maintain water quality, especially in areas prone to bacterial contamination or where water quality is uncertain.

Designing Effective Drainage to Prevent Waterlogging

Effective drainage systems are vital in managing waste water and excess rainwater, thereby preventing waterlogging and maintaining a hygienic environment. Proper design involves:

- Site Assessment: Conduct a survey to identify natural slopes and low-lying areas that are prone to water accumulation.

- Drain Placement and Slope: Install drains with appropriate gradients—typically 1-2% slope—to facilitate swift water runoff away from the shed structures.

- Drain Types: Choose between open trenches, covered drains, or underground pipes based on the volume of water to be managed and site conditions.

- Disposal and Outlets: Connect drains to designated disposal points such as soak pits, drainage channels leading to natural water bodies, or constructed retention ponds to prevent backflow and water stagnation.

Types of Drainage Systems, Components, and Maintenance Requirements

| Drainage System Type | Components | Maintenance Requirements |

|---|---|---|

| Open Drainage System | Graded trenches, catch basins, outlet outlets | Regular cleaning of debris and sediment, inspection for blockages, clearing of obstructions |

| Covered or Pipe Drainage System | Underground pipes, junction chambers, outlets | Periodic flushing to remove silt, inspection of joints for leaks, prompt repairs of cracks or damages |

| French Drain System | Perforated pipes surrounded by gravel or crushed stone, surface grading | Monitoring for clogging, replacement of gravel if necessary, ensuring proper slope is maintained |

Proper maintenance ensures that drainage systems function effectively over time. Regular inspections and cleaning prevent blockages caused by debris, mud, or organic matter, which can compromise drainage efficiency and lead to waterlogging or disease outbreaks.

Guidelines for Ensuring Water Quality and Sanitation

Maintaining high water quality and sanitation standards is crucial for animal health and productivity. Key guidelines include:

- Regular testing of water sources for bacterial contamination, nitrates, and other pollutants.

- Ensuring water storage tanks are sealed and cleaned periodically to prevent algae growth and bacterial proliferation.

- Implementing disinfection protocols using approved sanitizers to reduce pathogenic microorganisms.

- Designing drainage to prevent stagnation of water, which can serve as breeding grounds for vectors such as mosquitoes and flies.

- Promoting good hygiene practices among farm workers, including regular cleaning of water troughs and drainage channels.

- Using biosecurity measures to prevent contamination from external sources, especially during heavy rains or floods.

Consistent monitoring and maintenance of water and drainage systems significantly contribute to the overall health, safety, and productivity of cattle within the shed environment.

Fencing and Security Measures

Implementing effective fencing and security protocols is vital for safeguarding cattle from predators, theft, and unauthorized access. Proper fencing not only provides physical protection but also helps maintain a controlled environment conducive to cattle health and well-being.

Enhancing security with well-designed fencing, secure gates, locks, and surveillance systems creates a comprehensive safeguard around the cattle shed. This integrated approach minimizes risks and ensures the safety of livestock at all times.

Fencing Options for Cattle Protection

Choosing the appropriate fencing type depends on factors such as cattle size, behavior, local predator threats, climate conditions, and budget constraints. Various fencing options offer different levels of durability, safety, and ease of maintenance.

- Barbed Wire Fencing: Commonly used for large-scale boundaries, barbed wire provides a strong physical barrier that deters predators and prevents cattle from escaping. It is cost-effective but requires regular maintenance to prevent rust and sagging.

- Woven Wire Fencing: Also known as field fencing, it consists of galvanized wire woven into a tight mesh. Suitable for smaller enclosures and high-security areas, it offers good visibility and safety for cattle.

- Electric Fencing: Incorporates conductive wires attached to energizers delivering shocks upon contact. Ideal for temporary or adjustable boundaries, electric fencing effectively deters predators and cattle from crossing boundaries.

- Wooden Fencing: Typically used for aesthetic or boundary demarcation purposes, wooden fences are durable when properly treated but may be less effective for security unless reinforced or combined with other fencing types.

Installation Procedures for Durable and Safe Fencing

Proper fencing installation ensures maximum durability, safety, and longevity. The following steps Artikel best practices for installing cattle fencing:

- Survey the designated boundary area, marking the Artikel accurately to ensure proper alignment and coverage.

- Prepare the ground by clearing vegetation, debris, and any obstacles that could compromise fence stability.

- Install corner and end posts at regular intervals, typically every 8 to 12 meters, using sturdy materials such as treated wood or galvanized steel.

- Position line posts between the corner posts, maintaining consistent spacing to support the fencing wire or mesh evenly.

- Attach the chosen fencing material securely to the posts, ensuring tightness to prevent sagging or gaps that could allow cattle or predators to breach.

- Inspect the entire fence line for weak points, sharp edges, or loose attachments, making necessary adjustments for safety and durability.

Using high-quality materials and following precise installation procedures significantly reduces maintenance needs and enhances security.

Fencing Materials and Tools

Organizing the right materials and tools prior to fencing installation facilitates efficiency and ensures quality workmanship. The essential items include:

- Materials:

- Galvanized wire (barbed or woven)

- Electric fencing wires and energizers

- Treated wooden or steel posts

- Insulators for electric fences

- Gate hinges and latch systems

- Concrete or gravel for post setting

- Tools:

- Post driver or hammer

- Wire cutters and pliers

- Drilling machine (for electric fence insulators)

- Level and measuring tape

- Shovels and spades

- Clamp or tensioning device for wire

Additional Security Features

Beyond physical barriers, integrating supplementary security measures enhances overall safety. These include:

Gates and locks should be robust, lockable, and easy to operate, preventing unauthorized access and ensuring quick entry when needed.

- Gates: Opt for heavy-duty, galvanized gates with secure latch mechanisms. Properly installed gates facilitate safe ingress and egress for personnel and livestock.

- Locks: Use high-quality padlocks or padlock systems resistant to weather and tampering, ensuring livestock safety during off-hours.

- Surveillance Systems: Install CCTV cameras at strategic points around the perimeter. Visible security cameras act as deterrents and aid in monitoring activities in real-time or reviewing footage for suspicious behavior.

- Lighting: Adequate lighting around gates and fencing enhances visibility at night, discourages trespassers, and facilitates safe handling of cattle during early or late hours.

Interior Layout and Equipment

Designing an effective interior layout for a cattle shed is crucial for ensuring cattle comfort, health, and productivity. Proper organization of feeding, resting, and working areas within the shed facilitates efficient farm management and promotes optimal animal welfare. This segment Artikels best practices for arranging these zones, the essential equipment required, and the importance of space optimization.

Efficient interior layout involves creating distinct zones that serve specific functions while maximizing the use of available space. Strategic placement of equipment and pathways reduces congestion, minimizes stress for the animals, and simplifies daily farm operations. Implementing a well-planned layout enhances overall productivity and supports the long-term sustainability of cattle rearing activities.

Organization of Feeding, Resting, and Working Areas

Effective organization of the interior space involves delineating areas dedicated to feeding, resting, and operational activities such as cleaning and health checks. Each zone must be designed to meet the specific needs of the cattle, ensuring comfort and ease of access.

- Feeding Area: Should be positioned to allow easy access for cattle and farm workers. Feeders should be arranged to prevent competition and ensure even distribution of feed. Proper height and spacing facilitate efficient feeding and reduce wastage.

- Resting Area: Typically consists of bedding zones that offer a comfortable and dry environment. Resting zones should be spacious enough to prevent overcrowding, which can cause stress and health issues.

- Working Area: Includes pathways and zones designated for routine management tasks such as cleaning, health checks, and medication administration. These areas should be clear of obstructions for smooth movement of personnel and equipment.

Layout Plan with Zones, Equipment, and Functions

A well-designed layout plan enhances operational efficiency and cattle well-being. The table below illustrates a typical interior arrangement, specifying zones, their primary equipment, and functions.

| Zone | Equipment | Function |

|---|---|---|

| Feeding Zone |

|

Provide easy access to nutritious feed, minimize wastage, and ensure all cattle are adequately nourished. |

| Resting Zone |

|

Offer comfortable and dry resting areas that promote health and reduce stress. |

| Watering Area |

|

Supply clean, fresh water continuously, encouraging adequate hydration and overall health. |

| Cleaning & Management Zone |

|

Facilitate sanitation, waste removal, and daily maintenance activities to prevent disease. |

| Working Area |

|

Ensure smooth management operations, including health checks, vaccinations, and equipment handling. |

Essential Equipment and Their Descriptions

Equipping the cattle shed with essential tools and devices is fundamental for maintaining hygiene, health, and operational efficiency.

- Feeders: Devices such as troughs or self-feeding systems designed to deliver feed efficiently while minimizing wastage. They can be made of durable materials like concrete or plastic.

- Waterers: Automatic or manual water troughs providing clean, fresh water. Automatic waterers reduce labor and ensure consistent water availability.

- Cleaning Tools: Hoses, scrapers, brushes, and disinfectants used to clean the shed regularly, preventing disease and maintaining hygiene standards.

- Lighting Fixtures: Proper lighting ensures visibility and safety for farm workers, particularly during early morning or late evening operations.

- Health and Monitoring Equipment: Includes thermometers, health check stations, and vaccination equipment essential for cattle management.

Significance of Space Optimization for Cattle Comfort and Productivity

Optimal space utilization within the cattle shed plays a vital role in ensuring animal welfare and maximizing productivity. Adequate space reduces stress, prevents injuries, and promotes natural behaviors such as lying down, grazing, and social interactions.

Overcrowding can lead to increased disease transmission, competition for resources, and decreased growth rates. Conversely, excessive space can be inefficient and costly. Striking a balance through precise planning ensures cattle remain comfortable and farm operations stay economically sustainable. Examples from successful dairy farms indicate that providing at least 2.5 to 3 square meters per mature cow fosters better health and higher milk yields.

Implementing space-efficient layouts, such as group housing or adjustable partitions, allows flexibility to accommodate varying herd sizes and growth stages. This approach not only enhances animal well-being but also improves labor efficiency and overall farm profitability.

Last Recap

In summary, creating an effective cattle shed involves meticulous planning, appropriate construction practices, and thoughtful design elements that prioritize animal comfort and operational efficiency. By applying these insights, you can establish a safe, sustainable, and productive environment for your livestock that supports your agricultural goals.