Maintaining the ideal temperature in poultry housing is crucial for the health, productivity, and overall well-being of your flock. This guide, “How to Manage Poultry Temperature,” delves into the multifaceted world of climate control in poultry farming, exploring the science behind thermoregulation and the practical application of various management techniques. From understanding the physiological responses of chickens to environmental factors, to implementing cutting-edge heating, cooling, and ventilation systems, this resource provides a comprehensive overview to optimize poultry environments.

This comprehensive guide will navigate through the intricacies of environmental assessment, from the selection of appropriate heating and cooling systems to strategic ventilation plans. You’ll learn to interpret temperature fluctuations, utilize monitoring tools, and develop a keen understanding of how to mitigate extreme weather challenges. The guide also emphasizes the importance of building design, litter management, and even vaccination strategies to ensure optimal conditions for different poultry stages, ultimately contributing to a thriving and productive poultry operation.

Introduction to Poultry Temperature Management

Maintaining the correct environmental temperature is paramount for successful poultry farming. This directly impacts bird health, growth rates, feed conversion efficiency, and overall profitability. Understanding and effectively managing temperature is a cornerstone of good poultry husbandry.

Significance of Optimal Temperature for Poultry Health and Productivity

Optimal temperature control significantly influences various aspects of poultry production. These factors contribute to both bird welfare and economic viability.

- Metabolic Rate: The bird’s metabolic rate is directly influenced by environmental temperature. Maintaining an optimal temperature range minimizes the energy expenditure required for thermoregulation, allowing birds to allocate more energy towards growth and egg production.

- Immune System Function: Stress caused by temperature extremes can suppress the immune system, making birds more susceptible to diseases. Optimal temperatures support a robust immune response, reducing the incidence of illness and the need for medication.

- Feed Conversion Ratio (FCR): The FCR, a measure of how efficiently birds convert feed into body weight or eggs, is highly dependent on temperature. Birds in optimal temperature conditions consume feed more efficiently, leading to better FCR and reduced feed costs.

- Egg Production: In laying hens, consistent temperatures are crucial for maintaining egg production. Temperature fluctuations can lead to decreased egg laying rates, smaller egg sizes, and reduced eggshell quality.

- Growth Rate: Broiler chickens grow rapidly, and their growth rate is closely tied to temperature. Optimal temperatures support faster growth, allowing birds to reach market weight sooner.

Challenges Associated with Temperature Fluctuations in Poultry Housing

Poultry housing presents numerous challenges regarding temperature control. These challenges often necessitate proactive management strategies.

- External Weather Conditions: Ambient temperature variations, especially seasonal changes, significantly impact the internal temperature of poultry houses. Managing these external influences is a constant challenge.

- Building Design and Insulation: The design and insulation of the poultry house play a critical role in maintaining a stable internal temperature. Poorly insulated structures are highly susceptible to temperature fluctuations.

- Ventilation Systems: Ventilation systems are essential for removing excess heat, moisture, and harmful gases. Improperly designed or managed ventilation can exacerbate temperature problems.

- Stocking Density: High stocking densities generate significant heat from the birds themselves. This can lead to overheating, particularly in warmer climates.

- Bird Age and Breed: The age and breed of the birds influence their thermoregulatory capabilities. Young chicks and certain breeds are more vulnerable to temperature extremes.

Common Consequences of Inadequate Temperature Control in Different Poultry Breeds

Inadequate temperature control can lead to various adverse effects, the severity of which depends on the breed and age of the birds. Understanding these consequences is essential for proactive management.

- Broilers: In broilers, cold stress can lead to reduced growth rates, increased feed consumption (as birds try to maintain body temperature), and higher mortality rates. Heat stress can cause panting, reduced feed intake, and increased susceptibility to diseases. For instance, studies have shown that broiler chickens exposed to temperatures above 32°C (89.6°F) can experience a significant decrease in weight gain, as much as 10-15% compared to birds kept at optimal temperatures.

- Laying Hens: Cold stress can lead to decreased egg production, smaller egg sizes, and increased feed consumption. Heat stress can result in reduced eggshell quality, thinner eggshells, and a decline in overall egg production. For example, research indicates that laying hens exposed to temperatures above 30°C (86°F) can experience a drop in egg production of up to 20% or more.

- Breed-Specific Vulnerabilities: Certain breeds are more susceptible to temperature extremes. For example, heavier breeds of broilers may be more prone to heat stress due to their higher metabolic rates and greater body mass. Similarly, breeds of laying hens with high egg production rates may be more sensitive to temperature fluctuations.

- Impact on Mortality Rates: Both cold and heat stress can significantly increase mortality rates, particularly in young chicks. For instance, during severe heat waves, poultry farms can experience substantial losses due to heatstroke, with mortality rates spiking dramatically.

- Disease Susceptibility: Inadequate temperature control weakens the immune system, making birds more vulnerable to various diseases. For example, respiratory diseases, such as infectious bronchitis, are more prevalent in birds experiencing cold stress.

Understanding Poultry Thermoregulation

Poultry thermoregulation is the process by which birds maintain a stable internal body temperature, despite fluctuations in the external environment. This is crucial for their survival and optimal performance. Understanding the mechanisms involved, and how they vary with factors like age and breed, is fundamental to effective poultry management.

Natural Thermoregulatory Mechanisms in Poultry

Birds employ a combination of behavioral and physiological mechanisms to regulate their body temperature. These mechanisms are finely tuned to maintain a core temperature that supports metabolic functions.

- Behavioral Responses: Birds actively seek or avoid heat. This includes:

- Panting: Rapid, shallow breathing increases evaporative heat loss. This is especially noticeable in chickens during hot weather.

- Seeking Shade: Birds move to shaded areas to reduce exposure to direct sunlight.

- Huddling: Chicks huddle together to conserve heat, especially in cold conditions. This behavior reduces the surface area exposed to the cold.

- Fluffing Feathers: Birds fluff their feathers to trap air, providing insulation against both heat and cold.

- Bathing: Dust bathing helps remove parasites and can also aid in cooling.

- Altering Activity Levels: Birds reduce activity during extreme temperatures to minimize metabolic heat production.

- Physiological Responses: Internal processes are also involved in temperature regulation:

- Evaporative Cooling: Panting and gular fluttering (rapid vibration of the throat) increase evaporative cooling from the respiratory tract.

- Peripheral Vasodilation/Vasoconstriction: Blood vessels near the skin surface dilate (widen) in hot conditions to increase heat loss and constrict (narrow) in cold conditions to conserve heat.

- Metabolic Rate Adjustment: Metabolic rate increases in cold conditions to generate heat through muscle activity and shivering.

- Feather Adjustment: Piloerection (raising of feathers) can trap a layer of air to act as an insulator in cold weather.

Influence of Breed, Age, and Size on Thermoregulation

A bird’s ability to regulate its body temperature is significantly influenced by its breed, age, and size. These factors impact the efficiency of thermoregulatory mechanisms.

- Breed: Different breeds have varying tolerances to heat and cold.

- Heat Tolerance: Breeds originating from warmer climates, like Leghorns, tend to have better heat tolerance due to their higher surface area to body mass ratio and efficient panting mechanisms. They also have less feather cover.

- Cold Tolerance: Breeds from colder climates, such as Orpingtons, often have greater cold tolerance, with denser feathering and larger body sizes to conserve heat.

- Age: Young birds are less capable of thermoregulation than adults.

- Chicks: Chicks have a poorly developed thermoregulatory system. They rely heavily on external heat sources to maintain their body temperature.

- Growers: As birds mature, their thermoregulatory abilities improve. They develop more efficient mechanisms for heat loss and conservation.

- Adults: Adult birds have fully developed thermoregulatory systems, enabling them to withstand a wider range of environmental temperatures.

- Size: Body size affects the surface area to volume ratio, which influences heat exchange.

- Smaller Birds: Smaller birds have a higher surface area to volume ratio, making them more susceptible to heat loss in cold conditions and heat gain in hot conditions.

- Larger Birds: Larger birds have a lower surface area to volume ratio, helping them retain heat in cold weather and, to a certain extent, resist overheating in warm conditions.

Thermoregulatory Differences Between Chicks, Growers, and Adult Birds

The thermoregulatory capabilities of poultry change dramatically throughout their life stages. This is reflected in their responses to environmental temperature.

- Chicks (0-4 weeks):

- High Dependence on External Heat: Chicks have limited ability to generate and retain heat. Brooding is essential to provide an appropriate thermal environment.

- Limited Insulation: Down feathers provide minimal insulation.

- Immature Physiological Mechanisms: Panting and peripheral vasodilation are less efficient.

- Example: A newly hatched chick cannot survive for long in temperatures below 30°C (86°F).

- Growers (5-16 weeks):

- Developing Thermoregulatory Systems: They gradually develop more efficient heat production and dissipation mechanisms.

- Increased Insulation: Feather development provides improved insulation.

- Enhanced Behavioral Responses: Growers begin to exhibit more sophisticated behavioral responses to temperature changes, like seeking shade or adjusting activity levels.

- Example: A grower bird can tolerate a wider range of temperatures than a chick, but is still vulnerable to extreme conditions.

- Adult Birds (16+ weeks):

- Mature Thermoregulatory Systems: Adult birds have fully developed physiological and behavioral mechanisms.

- Optimal Insulation: A complete feather coat provides excellent insulation.

- Efficient Heat Dissipation: Panting and peripheral vasodilation are highly effective.

- Example: Adult birds can tolerate temperatures ranging from below freezing to over 30°C (86°F), provided they have access to appropriate resources like water and shade.

Assessing Environmental Conditions

Understanding and effectively managing the environment within a poultry house is crucial for maintaining optimal bird health and productivity. This involves carefully monitoring and controlling several key environmental factors that directly influence the birds’ ability to regulate their body temperature. A thorough assessment of these conditions allows for timely interventions to prevent heat stress, cold stress, and other environmental challenges that can negatively impact poultry performance.

Key Environmental Factors Affecting Poultry Temperature

Several environmental elements significantly influence the temperature experienced by poultry. Recognizing and understanding the impact of each factor is fundamental to effective temperature management.

- Ambient Temperature: This is the air temperature surrounding the birds and is the most direct influence on their body temperature. Maintaining the appropriate ambient temperature based on the birds’ age and breed is essential. For example, newly hatched chicks require significantly warmer temperatures (around 90-95°F or 32-35°C) than mature birds.

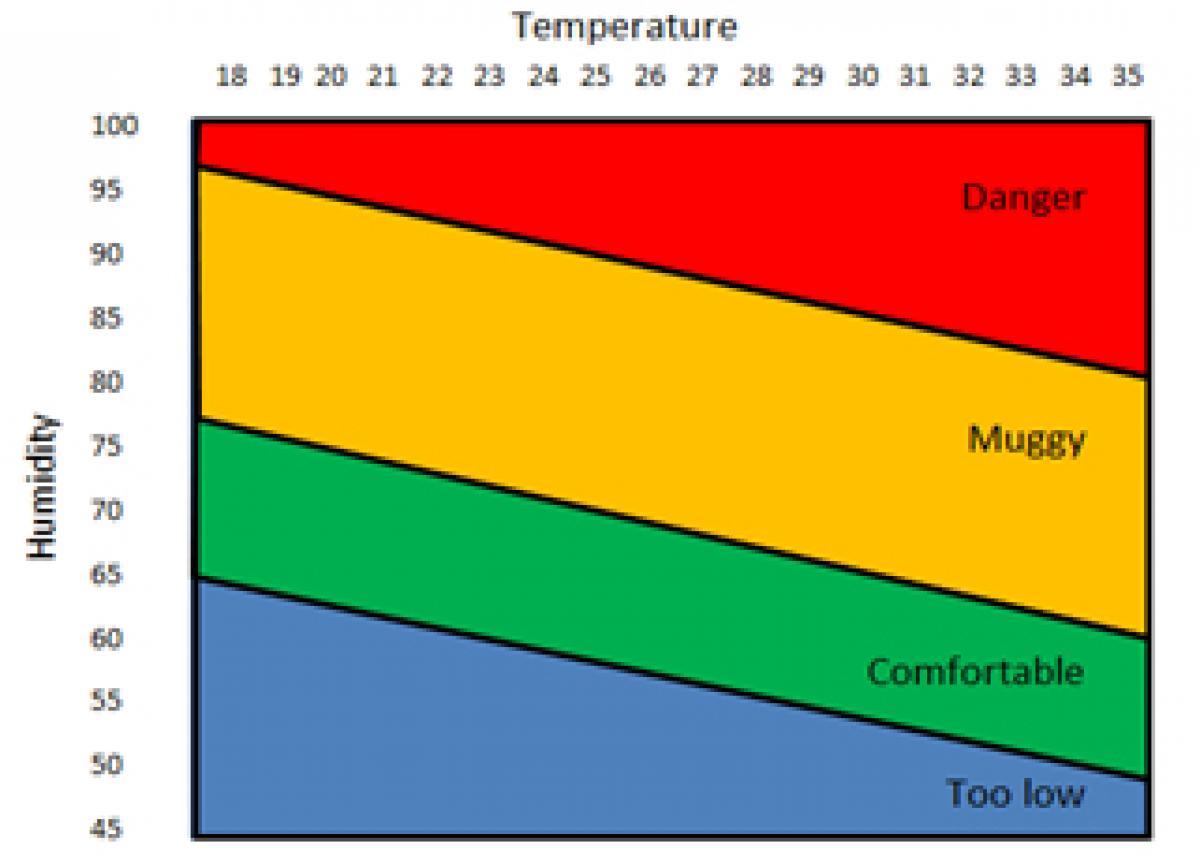

- Humidity: Relative humidity (RH) represents the amount of moisture in the air. High humidity can hinder a bird’s ability to cool itself through panting and respiration, increasing the risk of heat stress. Conversely, very low humidity can lead to dry air, potentially damaging the respiratory system. Ideal humidity levels generally range from 50% to 70%.

- Ventilation: Proper ventilation ensures adequate airflow within the poultry house. This helps to remove excess heat, moisture, ammonia, and other harmful gases. Effective ventilation systems are crucial for maintaining a consistent and healthy environment. Insufficient ventilation can lead to a buildup of heat and humidity, contributing to heat stress.

- Solar Radiation: Sunlight can directly increase the temperature inside a poultry house, particularly if the building is not properly insulated or shaded. The intensity of solar radiation varies depending on the time of day, season, and geographical location.

- Wind Speed: Wind can have a cooling effect, particularly during warmer months. However, excessive drafts can lead to cold stress, especially in young birds.

Using Monitoring Tools for Accurate Temperature Readings

Accurate temperature readings are fundamental to effective poultry temperature management. Various tools are available to monitor environmental conditions, providing valuable data for informed decision-making.

- Thermometers: Thermometers are essential for measuring ambient temperature. They come in various forms, including:

- Digital Thermometers: These provide precise temperature readings and are often equipped with memory functions to record temperature fluctuations over time.

- Analog Thermometers: These are more traditional thermometers, often using a liquid-filled bulb to indicate temperature. They are generally less expensive but may be less accurate than digital options.

- Infrared Thermometers: These allow for non-contact temperature measurement of surfaces, such as the birds themselves or the floor of the poultry house.

- Hygrometers: These instruments measure relative humidity. Many digital thermometers also include a hygrometer, providing both temperature and humidity readings in a single device.

- Data Loggers: These devices automatically record temperature and humidity readings over time. Data loggers are invaluable for tracking environmental changes and identifying trends within the poultry house.

- Anemometers: These measure wind speed. While not directly related to temperature, they provide valuable information for evaluating the effectiveness of ventilation systems.

- Placement Considerations: It’s important to place monitoring tools strategically within the poultry house. Position thermometers and hygrometers at bird level, away from direct sunlight and drafts, to obtain accurate readings of the environment experienced by the birds. Consider placing multiple sensors in different areas of the house to account for temperature variations.

Designing a System for Tracking Temperature Variations

Establishing a system for tracking temperature variations is essential for proactive temperature management. This involves regular monitoring, data recording, and analysis to identify trends and implement necessary adjustments.

- Regular Monitoring Schedule: Implement a consistent monitoring schedule, such as taking temperature and humidity readings at least twice daily, ideally in the morning and afternoon, to capture daily fluctuations. For example, readings could be taken at 8:00 AM and 4:00 PM.

- Data Recording Methods: Choose a method for recording temperature and humidity readings. Options include:

- Manual Recording: Use a logbook or spreadsheet to record readings. This method is simple and inexpensive but can be time-consuming.

- Automated Data Logging: Utilize data loggers that automatically record readings at set intervals. This method provides more detailed data and reduces the need for manual recording.

- Data Analysis and Interpretation: Analyze the recorded data to identify temperature trends. Calculate daily and weekly averages to understand overall temperature patterns. Compare readings with established temperature guidelines for the birds’ age and breed.

- Actionable Insights and Adjustments: Use the analyzed data to inform management decisions. If temperature fluctuations are excessive or deviate from the optimal range, adjust ventilation, heating, or cooling systems accordingly. For instance, if the morning temperature is consistently below the target range, increase the heating duration or intensity.

- Example Data Tracking System: A poultry farmer might record daily high and low temperatures and humidity levels in a spreadsheet. They could then graph this data weekly to visualize temperature trends. If the average weekly temperature consistently exceeds the optimal range for the birds, the farmer could increase ventilation or add cooling measures, such as evaporative cooling pads.

Heating Systems for Poultry Houses

Maintaining the correct temperature within a poultry house is crucial for the health, growth, and productivity of the birds. Efficient heating systems are therefore essential, particularly during colder months or in regions with variable climates. Selecting the right heating system depends on several factors, including the size of the poultry house, the type of birds being raised, and the local climate conditions.

This section will delve into the various heating systems commonly used in poultry houses, offering a comparative analysis to help producers make informed decisions.

Heating System Options

Several different heating systems are employed in poultry houses, each with its own advantages and disadvantages. Understanding the nuances of each system is vital for optimizing energy efficiency and ensuring the well-being of the flock.

Brooders

Brooders are localized heating units specifically designed for newly hatched chicks and young birds. They provide a concentrated source of heat in a smaller area, allowing the chicks to regulate their body temperature more effectively.

- Types of Brooders: Common types include gas brooders (using propane or natural gas), electric brooders (using infrared bulbs or heating elements), and radiant brooders. Gas brooders are often favored for larger operations due to their higher heat output and lower operating costs compared to electric options, although electric brooders are generally safer.

- Placement and Management: Brooders are typically suspended from the ceiling and adjusted in height as the chicks grow. Proper placement ensures even heat distribution, while regular monitoring of the chicks’ behavior is essential to determine if the temperature is adequate. Chicks that are huddled together are often cold, while chicks that are spread out and panting are likely too warm.

Radiant Heaters

Radiant heaters, also known as infrared heaters, emit infrared radiation that directly warms objects, including the birds and the floor, rather than heating the air. This can lead to more efficient heat distribution and reduced energy consumption.

- How They Work: Radiant heaters utilize a combustion process (typically with propane or natural gas) or electric elements to produce infrared heat. The heat is then directed downwards towards the floor and the birds.

- Advantages: Radiant heaters offer several advantages, including localized heating, which reduces drafts and allows for lower overall air temperatures, and increased energy efficiency because they directly heat the birds.

- Disadvantages: Radiant heaters can be more expensive to install than some other options, and the heat distribution may not be as uniform as with forced-air systems. They may also pose a fire hazard if not properly maintained.

Forced-Air Furnaces

Forced-air furnaces are a more general heating solution, using a combustion process (often with propane, natural gas, or oil) to heat the air, which is then distributed throughout the poultry house via a network of ducts and vents.

- How They Work: The furnace heats air, which is then circulated through the poultry house by a fan. The system can be controlled with a thermostat to maintain a consistent temperature.

- Advantages: Forced-air furnaces can provide uniform heating throughout the entire poultry house and are effective in larger operations. They can also be integrated with ventilation systems for better air quality.

- Disadvantages: Forced-air furnaces can be less energy-efficient than radiant systems, and the air movement can create drafts that can chill the birds. Maintenance can also be more complex than with simpler systems.

Comparative Analysis of Heating Methods

The following table provides a comparative analysis of the pros, cons, and cost considerations for the heating systems discussed. Note that cost estimates are approximate and can vary based on the size of the poultry house, the specific equipment used, and local market conditions.

| Heating System | Pros | Cons | Cost |

|---|---|---|---|

| Brooders | Localized heat, efficient for chicks, relatively inexpensive to install. | Limited to a specific area, may require multiple units for large houses, less efficient for older birds. | $50 – $500 per unit (depending on type and size) |

| Radiant Heaters | Efficient heating, reduced drafts, targeted heating, lower operating costs compared to forced air. | Higher initial investment, potential fire hazard if not properly maintained, uneven heat distribution if poorly placed. | $200 – $1,000 per unit (depending on size and fuel type) |

| Forced-Air Furnaces | Uniform heating, suitable for large houses, can be integrated with ventilation systems. | Higher operating costs, potential for drafts, more complex maintenance. | $1,000 – $5,000 (depending on size and fuel type) |

Best Practices for Installation and Maintenance

Proper installation and regular maintenance are crucial for the efficient and safe operation of any poultry house heating system. Following these best practices can help to extend the lifespan of the equipment, minimize energy consumption, and protect the health and safety of the birds.

- Professional Installation: Ensure that all heating systems are installed by qualified professionals who are familiar with the specific equipment and local building codes. This is particularly important for gas-fired systems to ensure safe operation and prevent carbon monoxide buildup.

- Regular Inspections: Conduct regular inspections of all heating systems, including checking for leaks, blockages, and proper ventilation. This should be done at least once a year, and more frequently during the heating season.

- Cleaning and Maintenance: Clean all heating components regularly, including burners, reflectors, and vents. Replace filters as needed, and lubricate moving parts according to the manufacturer’s recommendations.

- Fuel Storage and Safety: Store fuel (propane, natural gas, oil) safely and in accordance with local regulations. Ensure that fuel lines are properly installed and maintained, and that there are no leaks. Install carbon monoxide detectors in the poultry house.

- Ventilation Management: Proper ventilation is essential for removing moisture and ammonia from the poultry house, which can affect the efficiency of the heating system and the health of the birds. Ensure that the ventilation system is working properly and that it is balanced with the heating system.

- Emergency Procedures: Develop and implement emergency procedures in case of a heating system failure, including backup heating options and procedures for protecting the birds from cold stress.

Cooling Systems for Poultry Houses

Managing temperature in poultry houses is a year-round challenge, and effective cooling systems are crucial for maintaining bird health, productivity, and welfare, particularly in hot climates. These systems work to reduce the ambient temperature within the poultry house, mitigating the effects of heat stress on the birds. Several cooling strategies can be employed, each with its own advantages and disadvantages depending on the climate, the size of the poultry operation, and the resources available.

Different Cooling Strategies

Several cooling strategies are used in poultry houses to provide optimal thermal conditions. These methods include evaporative cooling, fogging systems, and ventilation. Each system has distinct operating principles and varying levels of effectiveness, contingent on environmental conditions and the specific requirements of the poultry operation.

- Evaporative Cooling: This method utilizes the principle of evaporative cooling, where water evaporates and absorbs heat from the surrounding air. This is commonly achieved through the use of cooling pads or a combination of pads and fans.

- Fogging Systems: Fogging systems release fine water droplets into the air, which evaporate and cool the environment. These systems can provide rapid cooling and are often used in conjunction with ventilation.

- Ventilation: Proper ventilation is essential for removing heat and moisture from the poultry house. This can be achieved through natural or mechanical ventilation systems, which facilitate the exchange of air and maintain a comfortable environment.

Principles Behind Evaporative Cooling and Its Effectiveness in Hot Climates

Evaporative cooling is based on the physical principle that when water evaporates, it absorbs heat from its surroundings, thereby cooling the air. This process is particularly effective in hot, dry climates where the air has a high capacity to absorb moisture.The effectiveness of evaporative cooling is primarily determined by the dry-bulb temperature (ambient temperature) and the wet-bulb temperature (temperature of the air after it has passed through a wet surface).

The difference between these two temperatures, known as the wet-bulb depression, indicates the potential cooling capacity.In hot, dry climates, the wet-bulb depression is often significant, making evaporative cooling a highly effective method. For instance, a poultry house in a region with a dry-bulb temperature of 35°C (95°F) and a wet-bulb temperature of 25°C (77°F) can experience a significant reduction in temperature through evaporative cooling.The effectiveness of evaporative cooling can be illustrated by the following formula:

Tout = T in

- (Efficiency × (T in

- T wb))

Where:

Tout = Outlet air temperature

Tin = Inlet air temperature

Twb = Wet-bulb temperature

A well-designed and maintained evaporative cooling system can significantly reduce the temperature within a poultry house, improving bird comfort and performance.

The efficiency of evaporative cooling systems can vary depending on the design and maintenance of the system. However, well-maintained systems can often achieve efficiencies of 70-90%.

Step-by-Step Procedure for Implementing a Simple Ventilation System in a Poultry House

Implementing a ventilation system involves several steps to ensure effective air exchange and temperature regulation within the poultry house. A basic system typically involves the use of fans and air inlets to circulate air and remove heat and moisture.

- Assessment of the Poultry House: Evaluate the size of the poultry house, the number of birds, and the climate conditions to determine the required ventilation rate.

- Fan Selection and Placement: Choose appropriate fans based on the required airflow (cubic feet per minute, CFM) and static pressure. Position the fans strategically to ensure uniform air distribution throughout the house. Typically, fans are placed at one end of the house, exhausting air.

- Inlet Design and Placement: Install air inlets along the sidewalls or ceiling to allow fresh air to enter the house. Inlets should be designed to direct the incoming air to mix with the existing air and prevent drafts directly on the birds.

- Wiring and Electrical Connections: Ensure all electrical connections are done by a qualified electrician and comply with local electrical codes.

- System Testing and Adjustment: After installation, test the system to ensure proper operation. Adjust the fan speeds and inlet openings to achieve the desired airflow and maintain optimal environmental conditions within the house.

- Regular Maintenance: Regularly clean the fans and inlets to prevent dust buildup and ensure efficient operation. Check and replace any worn-out parts as needed.

Ventilation Strategies for Temperature Control

Ventilation is a critical component of poultry temperature management, playing a vital role in maintaining a healthy and productive environment for birds. Effective ventilation removes excess heat, moisture, and harmful gases, such as ammonia, which can negatively impact bird health and performance. This section will explore the different types of ventilation systems and how to design an ideal ventilation plan for poultry houses.

Role of Ventilation in Poultry Houses

Ventilation serves multiple essential functions within a poultry house, directly influencing bird comfort and well-being. Its primary purpose is to remove heat generated by the birds’ metabolism and the heating systems, particularly in warmer climates or during peak bird density. Simultaneously, ventilation expels excess moisture produced by respiration, droppings, and water spills, preventing the build-up of humidity, which can lead to respiratory issues and the proliferation of pathogens.

Furthermore, ventilation dilutes and removes harmful gases like ammonia, carbon dioxide, and hydrogen sulfide, which are byproducts of manure decomposition and can cause respiratory problems, eye irritation, and reduced weight gain in poultry.

Types of Ventilation Systems

Ventilation systems are broadly classified into natural and mechanical systems, each with its own advantages and limitations depending on the climate and poultry house design.

- Natural Ventilation: Natural ventilation relies on the principles of air movement caused by wind and temperature differences. This is generally a cost-effective method, but it is heavily reliant on weather conditions.

- Ridge Vents: These are openings along the roof’s peak that allow warm air to escape. They are most effective in removing heat during warmer months.

- Side Wall Curtains/Openings: Adjustable curtains or openings along the sidewalls allow fresh air to enter and circulate. They are managed to control the air intake and prevent drafts.

- Stack Effect: This relies on the principle that warm air rises. In naturally ventilated houses, the difference in temperature between inside and outside creates an upward airflow.

- Mechanical Ventilation: Mechanical ventilation uses fans to actively move air in and out of the poultry house, providing greater control over airflow and environmental conditions.

- Tunnel Ventilation: This system uses large fans at one end of the house to draw air through the entire length of the house, creating a ‘tunnel’ of airflow. It is particularly effective for cooling birds in hot weather.

- Cross-Flow Ventilation: This system uses fans located along the sidewalls to draw air across the width of the house. It is generally less effective than tunnel ventilation for cooling but provides good overall air exchange.

- Negative Pressure Ventilation: Exhaust fans create a negative pressure inside the house, drawing fresh air in through inlets, typically located on the sidewalls or ceiling.

- Positive Pressure Ventilation: Supply fans force fresh air into the house, creating positive pressure, which then forces stale air out through openings.

- Evaporative Cooling Systems: Often integrated with mechanical ventilation, these systems use water to cool the incoming air before it enters the house. Pad-and-fan systems are a common example.

Suitability of Ventilation Systems for Different Climates

The choice of ventilation system is largely determined by the climate of the region and the type of poultry operation.

- Hot Climates: In hot climates, mechanical ventilation systems, particularly tunnel ventilation combined with evaporative cooling pads, are essential for maintaining bird comfort and productivity. The high airflow rates associated with tunnel ventilation effectively remove heat, while the evaporative cooling reduces the temperature of incoming air. For example, in broiler houses in the southern United States, tunnel ventilation can maintain temperatures several degrees cooler than ambient, significantly improving bird performance during the summer months.

- Temperate Climates: In temperate climates, a combination of natural and mechanical ventilation can be employed. Natural ventilation can be used during milder periods, while mechanical ventilation is used to supplement airflow during periods of extreme heat or cold. Cross-flow or negative pressure ventilation systems may be adequate for moderate climates.

- Cold Climates: In cold climates, mechanical ventilation is crucial to control humidity and remove harmful gases without excessively cooling the house. Minimum ventilation rates are maintained throughout the year to ensure air quality. Systems with good insulation and effective heating systems are necessary to balance ventilation with temperature control. Positive pressure ventilation systems can also be used to reduce drafts.

Designing an Ideal Ventilation Plan

Creating an effective ventilation plan requires careful consideration of several factors.

- Bird Density: Higher bird densities require higher ventilation rates to remove heat, moisture, and gases. The ventilation system must be sized to accommodate the peak heat and moisture production levels.

- Climate: The local climate dictates the type and capacity of the ventilation system. This involves assessing the highest and lowest expected temperatures, humidity levels, and prevailing wind patterns.

- House Design: The design of the poultry house, including its orientation, insulation, and the presence of features like ridge vents or curtain walls, influences the effectiveness of ventilation.

- Type of Poultry: Different poultry species and ages have different requirements. For example, broilers generate more heat than laying hens, and young chicks are more sensitive to drafts.

- Airflow Rate: The required airflow rate varies depending on the bird’s age, climate conditions, and the production phase. This can be calculated using formulas that consider the heat and moisture production rates of the birds.

- Equipment Selection: Selecting the appropriate fans, inlets, and evaporative cooling systems is critical. Fan performance curves and static pressure requirements should be carefully considered to ensure that the system operates efficiently.

- Control Systems: Automated control systems with sensors that monitor temperature, humidity, and gas concentrations are essential for maintaining optimal environmental conditions. These systems can automatically adjust the ventilation rate and other environmental controls.

The ideal ventilation plan often incorporates a staged approach, with different ventilation strategies used at different stages of the birds’ life cycle and during different times of the year. For example, during the brooding phase, minimum ventilation is used to maintain temperature and humidity levels. As the birds grow, ventilation rates increase to remove heat and moisture. During periods of extreme heat, tunnel ventilation and evaporative cooling may be employed to keep birds comfortable.

Insulation and Building Design

Proper insulation and thoughtful building design are fundamental to effective poultry temperature management. They create a stable thermal environment within the poultry house, minimizing the impact of external weather fluctuations and reducing the energy required for heating and cooling. Effective insulation and design not only improve bird comfort and productivity but also contribute to the overall efficiency and sustainability of poultry operations.

Importance of Insulation in Poultry Houses

Insulation plays a critical role in regulating the internal temperature of a poultry house. It acts as a barrier to heat transfer, slowing the movement of heat from areas of higher temperature to areas of lower temperature. This is crucial in both hot and cold climates.

- Heat Retention in Cold Weather: Insulation minimizes heat loss during winter months. By preventing heat from escaping the building, it reduces the need for supplemental heating, saving energy and costs. For instance, a well-insulated poultry house can maintain a temperature of 70°F (21°C) even when the outside temperature drops to 20°F (-7°C), significantly improving bird health and performance.

- Heat Reduction in Hot Weather: Insulation helps to keep the poultry house cooler during summer. It reduces the amount of solar radiation and external heat that penetrates the building, thereby decreasing the reliance on cooling systems. This can prevent heat stress in birds, which can lead to decreased feed intake, reduced growth rates, and increased mortality.

- Consistent Temperature Maintenance: Insulation contributes to more stable internal temperatures. This consistency is beneficial for bird health and productivity, as it reduces the stress caused by rapid temperature fluctuations.

- Condensation Control: Insulation can help to minimize condensation within the poultry house. Condensation can lead to wet litter, which promotes the growth of harmful bacteria and increases ammonia levels.

Building Materials and Their Impact on Heat Transfer

The choice of building materials significantly affects the thermal performance of a poultry house. Different materials have varying thermal properties, impacting how effectively they resist heat transfer.

- Insulation Materials: The primary function of insulation materials is to resist heat flow. Common insulation materials include fiberglass, spray foam, polystyrene, and polyurethane. The effectiveness of insulation is measured by its R-value. A higher R-value indicates better insulation performance. For example, a poultry house with R-20 insulation in the walls and R-30 in the ceiling will be more energy-efficient than one with lower R-values.

- Wall Materials: The materials used for the walls also influence heat transfer. Concrete, brick, and wood have different thermal properties. Concrete, for instance, has a higher thermal mass than wood, meaning it absorbs and releases heat more slowly. This can help to moderate temperature fluctuations but requires proper insulation to be effective.

- Roofing Materials: Roofing materials, such as metal, asphalt shingles, and tiles, also impact heat gain and loss. Light-colored roofing materials reflect more solar radiation than dark-colored materials, which can help to reduce heat gain during the summer.

- Air Sealing: Proper air sealing is crucial to prevent drafts and reduce heat loss in winter and heat gain in summer. Cracks and gaps in the building envelope can significantly compromise the effectiveness of insulation.

Effect of Building Orientation and Design on Internal Temperature

The orientation and design of a poultry house can significantly influence its internal temperature. Strategic design choices can maximize natural ventilation and minimize solar heat gain.

- Building Orientation: The orientation of the poultry house relative to the sun’s path can affect the amount of solar radiation it receives. In hot climates, orienting the long axis of the building east-west can minimize solar heat gain during the hottest part of the day. In colder climates, a south-facing orientation can capture more solar heat during the winter.

- Roof Design: The design of the roof affects ventilation and heat gain. A sloped roof can facilitate natural ventilation, allowing hot air to escape. Overhangs can provide shade and reduce solar heat gain during the summer months.

- Ventilation Openings: The placement and size of ventilation openings, such as windows, vents, and fans, are crucial for temperature control. Proper ventilation helps to remove excess heat and moisture, maintaining a comfortable environment for the birds.

- Building Shape and Size: The shape and size of the poultry house can influence airflow and temperature distribution. A wider building may require more ventilation to ensure even temperature distribution.

- Example: Consider a poultry house in a hot, sunny region. If the building is oriented east-west and has a light-colored roof with overhangs, it will likely experience less heat gain compared to a building with a dark roof and a north-south orientation.

Temperature Management for Different Poultry Stages

Effective temperature management is crucial for poultry health, productivity, and overall well-being. The temperature requirements of chickens vary significantly depending on their age and developmental stage. This section will detail the specific temperature needs of chicks, growers, and layers, and provide strategies for adapting environmental conditions to meet those needs.

Temperature Requirements for Chicks, Growers, and Layers

Understanding the distinct temperature needs of different poultry stages is fundamental to successful poultry farming. Chicks, growers, and layers each have optimal temperature ranges that support their growth, development, and egg production. Deviation from these ranges can lead to stress, reduced feed conversion, and increased susceptibility to disease.

- Chicks (0-4 weeks): Newly hatched chicks are particularly vulnerable to temperature fluctuations because they haven’t yet developed their own thermoregulatory mechanisms. They require a warm environment to maintain body temperature. The initial brooder temperature should be approximately 90-95°F (32-35°C) measured at the chick level. This temperature should be gradually reduced by about 5°F (3°C) per week until it reaches around 70°F (21°C) or room temperature.

This reduction allows the chicks to acclimatize to ambient conditions and develop their own thermoregulatory capabilities.

- Growers (5-20 weeks): As chickens mature, their need for supplemental heat decreases. Growers, the birds in the growing phase, are more resilient to temperature changes than chicks. The ideal temperature range for growers is between 60-75°F (16-24°C). Maintaining a consistent temperature within this range promotes optimal growth and development. Providing adequate ventilation becomes increasingly important at this stage to manage humidity and air quality.

- Layers (20+ weeks): Mature laying hens thrive in a relatively stable and moderate temperature environment. The optimal temperature range for layers is generally considered to be between 65-75°F (18-24°C). Maintaining this range helps to maximize egg production, egg quality, and overall hen health. Excessive heat or cold can significantly impact egg laying rates and shell quality.

Adjusting Temperatures Based on Age and Developmental Stage

Adjusting temperatures based on the age and developmental stage of the birds is a dynamic process that requires constant monitoring and adaptation. The goal is to provide a comfortable and healthy environment that supports optimal growth, development, and production. Careful observation of the birds’ behavior is critical in determining whether temperature adjustments are needed.

- Monitoring Chick Behavior: Observe the chicks’ behavior to gauge their comfort level. If chicks huddle closely together under the heat source, it indicates they are cold and the temperature needs to be increased. If they are spread out, avoiding the heat source, the temperature may be too high and needs to be decreased. Evenly distributed chicks with normal activity levels suggest the temperature is appropriate.

- Gradual Temperature Adjustments: Avoid sudden drastic changes in temperature, which can stress the birds. Make gradual adjustments, typically decreasing the temperature by a few degrees per week for chicks. For growers and layers, make smaller adjustments as needed to maintain the target temperature range.

- Using Thermometers and Sensors: Employ accurate thermometers and environmental sensors to monitor the temperature in the poultry house. Place thermometers at chick level and in various locations within the house to ensure consistent readings. Modern poultry houses often use automated environmental control systems that regulate temperature, humidity, and ventilation based on sensor readings.

- Ventilation and Airflow Management: Adjust ventilation rates to manage temperature and humidity. Increased ventilation can help cool the house during warm weather, while reduced ventilation helps retain heat during cold weather. Proper airflow also helps to remove ammonia and other harmful gases.

Temperature Management Strategies During Extreme Weather Conditions

Extreme weather conditions, such as heat waves and cold snaps, present significant challenges to poultry temperature management. Proactive strategies are essential to mitigate the negative impacts of these conditions on bird health and productivity.

- Heat Waves: During heat waves, the primary goal is to prevent heat stress.

- Increase Ventilation: Maximize ventilation to remove heat from the house. Use fans to increase airflow and create a cooling effect.

- Provide Cool Water: Ensure access to plenty of fresh, cool water. Consider adding electrolytes to the water to help birds cope with heat stress.

- Reduce Bird Density: If possible, reduce the stocking density to provide more space and reduce the heat load.

- Sprinklers/Misting: Use sprinklers or misting systems to cool the air and reduce the ambient temperature.

- Shade: Provide shade outside the poultry house to reduce the amount of direct sunlight.

- Cold Snaps: During cold snaps, the primary goal is to maintain a warm environment.

- Insulation: Ensure the poultry house is well-insulated to minimize heat loss.

- Heating Systems: Operate heating systems, such as brooders, heaters, or radiant heat sources, to maintain the desired temperature.

- Reduce Ventilation: Reduce ventilation rates to conserve heat. Be careful not to compromise air quality by reducing ventilation too much.

- Check for Drafts: Seal any drafts in the poultry house.

- Provide Extra Bedding: Provide extra bedding to help the birds stay warm.

- Real-World Example: In the summer of 2023, many poultry farms in the Midwest experienced record-breaking heat waves. Farms that had implemented effective cooling strategies, such as increased ventilation and misting systems, saw significantly lower mortality rates and maintained higher egg production compared to farms without these measures. Conversely, during a severe cold snap in the winter of 2022, poultry farms in the Northeast that had inadequate heating and insulation experienced significant losses due to freezing temperatures.

Monitoring and Troubleshooting

Effective poultry temperature management necessitates continuous monitoring and a proactive approach to troubleshooting. This involves recognizing the subtle cues that indicate thermal stress in birds and having the knowledge and tools to diagnose and rectify temperature-related issues within the poultry house environment. Early detection and swift intervention are critical to minimizing production losses and ensuring the welfare of the flock.

Identifying Signs of Heat Stress and Cold Stress in Poultry

Poultry, unlike mammals, lack sweat glands and rely primarily on panting and changes in posture to regulate their body temperature. Recognizing the behavioral and physiological signs of heat stress and cold stress is crucial for timely intervention.

- Signs of Heat Stress: Heat stress can manifest in various ways, affecting the birds’ behavior and physical condition.

- Panting: Rapid, shallow breathing is a primary indicator of heat stress, as the bird attempts to dissipate heat.

- Wing Spreading: Birds will often extend their wings away from their bodies to increase surface area for heat loss.

- Lethargy and Reduced Activity: Birds become less active, spending more time lying down.

- Reduced Feed Intake: Birds reduce feed consumption, as the metabolic heat generated from digestion exacerbates heat stress.

- Increased Water Consumption: Water intake increases significantly as the bird attempts to cool itself.

- Pale Combs and Wattles: The comb and wattles may appear pale due to reduced blood flow.

- Mortality: In severe cases, heat stress can lead to sudden death.

- Signs of Cold Stress: Cold stress, on the other hand, can lead to the opposite effects.

- Huddling: Birds huddle together to conserve body heat.

- Shivering: Muscle contractions generate heat, resulting in shivering.

- Reduced Activity: Similar to heat stress, activity levels decrease.

- Increased Feed Intake: To generate more metabolic heat, birds will increase their feed consumption.

- Increased Water Consumption: Though less dramatic than in heat stress, water consumption may still increase.

- Frostbite: In severe cold, combs, wattles, and feet can develop frostbite.

- Increased Mortality: Prolonged exposure to cold can lead to mortality, particularly in young chicks.

Diagnosing and Addressing Temperature-Related Problems

Accurate diagnosis is essential for effective problem-solving in poultry temperature management. This involves a systematic approach to identifying the root cause of temperature-related issues and implementing appropriate corrective measures.

- Temperature Monitoring: Regularly monitor temperature readings throughout the poultry house, using thermometers and data loggers.

- Thermometer Placement: Place thermometers at various heights within the house, near the birds, and away from direct sunlight or drafts. Digital thermometers offer easy reading and allow for data storage.

- Data Logging: Employ data loggers to track temperature fluctuations over time. This data provides valuable insight into trends and identifies patterns.

- Ventilation System Inspection: Assess the ventilation system’s performance.

- Fan Operation: Verify that all fans are operating correctly and at the correct speeds.

- Air Inlet Inspection: Ensure air inlets are properly adjusted to provide adequate airflow.

- Airflow Patterns: Check airflow patterns throughout the house to eliminate dead spots or drafts.

- Heating and Cooling System Evaluation: Evaluate the performance of heating and cooling systems.

- Heater Maintenance: Regularly inspect and maintain heaters, ensuring proper fuel supply and burner function.

- Cooling Pad Inspection: Check cooling pads for proper saturation and cleanliness.

- Evaporative Cooler Function: Verify the proper functioning of evaporative coolers, including water supply and fan operation.

- Bird Behavior Observation: Observe bird behavior closely.

- Distribution Patterns: Observe how birds are distributed within the house. Huddling in cold weather or spreading out in hot weather provides clues.

- Feed and Water Consumption: Monitor feed and water consumption, as significant deviations from normal patterns can indicate temperature stress.

- Mortality Rates: Keep a close eye on mortality rates, as increased mortality can be a sign of temperature problems.

- Environmental Factors: Consider external environmental factors.

- Weather Conditions: Account for changes in external temperature, humidity, and wind conditions.

- Sunlight Exposure: Assess the impact of sunlight on the house, particularly in terms of heat gain.

Troubleshooting Tips for Heating and Cooling Systems

Maintaining the proper functioning of heating and cooling systems is essential for effective temperature management. Common issues and troubleshooting tips include:

- Heating System Problems:

- Heater Failure: If a heater fails, immediately identify the cause (fuel shortage, electrical malfunction, etc.) and implement repairs. Provide backup heating if possible.

- Uneven Heating: Check for drafts, blocked vents, or malfunctioning thermostats. Adjust the system to ensure even heat distribution.

- Fuel Supply Issues: Ensure a consistent fuel supply (propane, natural gas, etc.) and inspect fuel lines for leaks.

- Burner Problems: Clean burners regularly and replace faulty components as needed.

- Cooling System Problems:

- Fan Malfunction: Repair or replace malfunctioning fans. Ensure fans are sized correctly for the house.

- Cooling Pad Issues: Clean cooling pads regularly to remove debris and ensure proper water flow. Replace pads when they become clogged or damaged.

- Water Supply Problems: Ensure an adequate water supply to cooling pads and evaporative coolers. Check for leaks or blockages.

- Evaporative Cooler Issues: Maintain evaporative coolers properly, including cleaning, checking water pumps, and replacing pads as needed.

- Ventilation System Problems:

- Fan Capacity: Ensure the ventilation system has adequate capacity to remove heat and moisture.

- Air Inlet Issues: Adjust air inlets to maintain proper airflow. Ensure inlets are not blocked.

- Drafts: Seal any drafts in the house, especially around doors, windows, and vents.

- Thermostat Issues:

- Calibration: Calibrate thermostats regularly to ensure accurate temperature readings.

- Placement: Ensure thermostats are placed in the correct locations, away from direct sunlight or drafts.

- Malfunctions: Replace faulty thermostats.

- Building Issues:

- Insulation Problems: Check insulation for damage or degradation. Repair or replace insulation as needed.

- Air Leaks: Seal air leaks in the building to prevent heat loss or gain.

Emergency Preparedness

Maintaining optimal temperature in poultry houses is crucial for bird health and productivity. Unexpected events, such as power outages or equipment failures, can quickly disrupt these conditions, leading to significant losses. A proactive approach to emergency preparedness is therefore essential to mitigate risks and safeguard the flock. This involves anticipating potential issues, developing contingency plans, and ensuring resources are readily available to respond effectively.

Emergency Preparedness Checklist

Creating a comprehensive checklist is a foundational step in emergency preparedness. This checklist should encompass a range of potential scenarios and the corresponding actions required. Regular review and updates are necessary to maintain its effectiveness.

- Power Outage Response:

Prepare for potential power outages by having a backup power source, such as a generator, and ensuring it is regularly tested. The generator should be sized appropriately to power essential equipment, including heating, ventilation, and water systems. Store a supply of fuel and maintain it properly. Ensure that the generator is automatically transferrable and properly connected. Additionally, develop a communication plan to inform relevant personnel.

- Equipment Failure Response:

Establish a system for regular equipment maintenance and inspections to identify potential failures before they occur. Maintain a readily available inventory of spare parts for critical equipment, such as heaters, fans, and water pumps. Develop protocols for rapidly repairing or replacing malfunctioning equipment. Identify alternative solutions, like manual ventilation if the fans fail.

- Severe Weather Response:

Monitor weather forecasts and prepare for extreme temperatures, storms, or other severe weather events. Secure the poultry house to prevent structural damage and water intrusion. Ensure proper drainage to prevent flooding. Prepare for potential loss of utilities and have backup plans for heating, cooling, and water supply.

- Communication and Coordination:

Establish a clear communication plan to alert key personnel, including farm managers, veterinarians, and emergency services. Develop a chain of command to ensure efficient decision-making during emergencies. Keep contact information updated. Consider having a radio or satellite phone as a backup communication method.

- Water Supply:

Ensure a backup water supply is available, such as a well or stored water, in case of water supply disruptions. Consider water storage tanks or reservoirs to provide a reserve supply. Regularly check and maintain water sources and delivery systems.

- Feed Supply:

Have an adequate feed supply on hand to cover at least a few days in case of supply chain disruptions. Store feed properly to prevent spoilage and pest infestation. Consider establishing relationships with multiple feed suppliers to ensure a reliable source of feed.

- First Aid and Veterinary Supplies:

Maintain a well-stocked first-aid kit for birds, including essential medications and supplies. Establish a relationship with a veterinarian who can provide immediate assistance. Ensure personnel are trained in basic bird first aid.

Responding to Sudden Temperature Changes

Rapid temperature fluctuations can be highly detrimental to poultry. Understanding the potential impact of these changes and implementing swift responses is crucial. This involves constant monitoring and the ability to react promptly to deviations from the ideal temperature range.

- Monitoring:

Implement a robust monitoring system that includes regular temperature checks and continuous monitoring systems with alarms. Use thermometers placed at bird level and in different locations throughout the house to ensure accuracy. Regularly calibrate the monitoring equipment to ensure accuracy.

- Recognizing the Issue:

Be vigilant in recognizing the signs of temperature stress in birds. Observe the birds’ behavior for signs of cold or heat stress. This includes huddling, panting, or spreading out. If you observe such behaviors, take immediate action.

- Rapid Response:

If temperatures drop, quickly activate backup heating systems, such as propane heaters or portable heaters. Seal any drafts by closing windows and doors, and checking for cracks in the building. If temperatures rise, activate cooling systems, such as fans, foggers, or misters. Increase ventilation and provide access to cool, clean water. Adjust the bird density to reduce crowding, allowing for better airflow.

- Protective Measures:

Protect the birds from direct sunlight, particularly in hot weather. Ensure that the birds have access to shade and are not exposed to direct sunlight. In cold weather, provide bedding to insulate the birds from the cold floor. Monitor and address any issues with the ventilation system to ensure it is operating correctly.

- Documentation:

Document all temperature changes and the actions taken. Keep records of temperature readings, equipment failures, and response measures. Analyze these records to improve emergency preparedness and response strategies.

Backup Heating and Cooling Plans

Developing a detailed backup plan for heating and cooling is a critical aspect of emergency preparedness. This plan should Artikel specific actions and resources to be deployed in various scenarios.

- Heating Backup:

The primary backup heating method should be a generator-powered system. Have a sufficient fuel supply on hand, and ensure that the generator is regularly maintained. Consider using portable propane or kerosene heaters as a secondary backup, but exercise extreme caution to prevent fire hazards and carbon monoxide poisoning. In case of extreme cold, increase the depth of bedding to provide insulation.

Close ventilation inlets to minimize heat loss. An example of a real-life scenario would be the 2021 Texas power grid failure, where many poultry operations suffered significant losses due to the inability to heat their houses during a prolonged cold snap.

- Cooling Backup:

For cooling, the backup plan should focus on maintaining air circulation and providing access to cool water. In the event of a power outage, consider using portable generators to power fans. If generators are not available, explore the use of manual ventilation, opening windows and doors to promote airflow. Increase water access for birds to help them cool down.

Consider using ice packs or wet burlap sacks to cool the birds directly. An example of a real-life scenario would be a heatwave in the summer of 2022 in Europe, which led to significant poultry losses. The implementation of backup cooling systems was vital in minimizing losses.

- Resource Assessment:

Evaluate the resources available, including the number of birds, the size of the poultry house, and the type of existing heating and cooling systems. This assessment will help in determining the appropriate size and capacity of backup equipment. Consider the local climate and the frequency of extreme weather events when developing the backup plan.

- Training and Drills:

Train all personnel on the backup plan, including the operation of backup equipment and emergency procedures. Conduct regular drills to simulate emergency scenarios and test the effectiveness of the plan. Provide regular updates to personnel on any changes to the plan or the equipment. Regularly review and update the plan.

- Coordination with Suppliers and Services:

Establish relationships with local suppliers of fuel, generators, and repair services. Having pre-arranged contracts and contact information can speed up the response time during an emergency. Consider establishing a relationship with a local electrician to ensure the generator and electrical systems are properly installed and maintained.

Technology and Automation

Modern poultry farming increasingly relies on technology and automation to optimize various aspects of production, and temperature management is a key area where these advancements offer significant benefits. Implementing automated systems provides precise control over the environment, leading to improved bird welfare, reduced energy consumption, and enhanced operational efficiency. The integration of sensors, data analytics, and automated control systems transforms how poultry houses are managed, resulting in higher productivity and profitability.

Automated Temperature Control Systems in Poultry Farming

Automated temperature control systems represent a significant shift from manual methods. These systems utilize a network of sensors, controllers, and actuators to maintain optimal temperature conditions within poultry houses. They constantly monitor the environment and make adjustments to heating, cooling, and ventilation systems based on pre-programmed parameters or real-time data analysis.

- Components of Automated Systems: A typical automated temperature control system includes:

- Temperature Sensors: These sensors, strategically placed throughout the poultry house, measure air temperature at various locations and heights. These sensors are typically digital, providing accurate and continuous temperature readings.

- Controllers: These are the “brains” of the system, receiving data from the sensors and comparing it to the desired temperature set points. They then send signals to the actuators to adjust the heating, cooling, and ventilation equipment.

- Actuators: These are the components that physically adjust the environment. Examples include fans, heaters, cooling pads, and ventilation inlets and outlets.

- Software and User Interface: Sophisticated software allows farmers to set temperature set points, monitor environmental conditions, and analyze historical data. User-friendly interfaces, often accessible via computers or mobile devices, provide real-time information and allow for remote control.

- Benefits of Automation:

- Precise Temperature Control: Automated systems maintain consistent temperatures, minimizing fluctuations that can stress birds and impact performance.

- Reduced Labor Costs: Automation eliminates the need for manual temperature monitoring and adjustments, freeing up labor for other tasks.

- Improved Efficiency: Automated systems optimize the use of energy, reducing heating and cooling costs.

- Enhanced Bird Welfare: Maintaining optimal temperatures promotes bird health and productivity, reducing mortality rates.

- Data-Driven Decision Making: Systems log environmental data, enabling farmers to analyze trends and make informed decisions about farm management.

Sensors and Data Analytics for Improved Temperature Management

Sensors and data analytics play a crucial role in optimizing temperature management in poultry houses. These technologies provide real-time data and insights that allow for proactive adjustments to environmental conditions.

- Types of Sensors:

- Temperature Sensors: As mentioned earlier, these are fundamental for monitoring air temperature. They are placed at various locations within the poultry house to provide a comprehensive view of the thermal environment.

- Humidity Sensors: Humidity sensors measure the moisture content in the air, which is critical for maintaining optimal comfort levels and preventing respiratory issues in birds.

- Airflow Sensors: These sensors measure the speed and volume of air movement within the house, allowing for efficient ventilation control.

- Gas Sensors: Sensors that detect levels of ammonia, carbon dioxide, and other gases are important for air quality monitoring. High levels of these gases can negatively impact bird health and performance.

- Data Analytics and Applications:

- Real-time Monitoring: Data analytics platforms display real-time sensor data, providing farmers with instant feedback on environmental conditions.

- Trend Analysis: Historical data can be analyzed to identify patterns and trends in temperature fluctuations, allowing for proactive adjustments.

- Predictive Modeling: Advanced analytics can be used to predict future temperature conditions based on weather forecasts and historical data, enabling farmers to prepare for changes in advance.

- Automated Adjustments: Data-driven insights can be used to automate adjustments to heating, cooling, and ventilation systems, optimizing energy use and bird comfort.

- Example: A poultry farm in Iowa implemented a data analytics system that analyzed temperature and humidity data, alongside bird weight gain and feed conversion ratios. This allowed them to fine-tune their ventilation strategies, resulting in a 5% improvement in feed conversion and a 3% reduction in energy costs.

Integrating Temperature Monitoring with Farm Management Systems

Integrating temperature monitoring with other farm management systems provides a holistic approach to poultry production. This integration allows farmers to correlate environmental data with other factors, such as feed consumption, water intake, and bird performance, providing a comprehensive view of the farm’s operations.

- Integration Methods:

- Centralized Data Platforms: Data from temperature sensors and other farm management systems can be integrated into a centralized data platform, providing a single point of access for all information.

- Application Programming Interfaces (APIs): APIs allow different software systems to communicate with each other, enabling data exchange and synchronization.

- Cloud-Based Solutions: Cloud-based platforms offer scalability and accessibility, allowing farmers to access their data from anywhere with an internet connection.

- Benefits of Integration:

- Correlation of Data: Farmers can correlate temperature data with other parameters, such as feed consumption, water intake, and bird weight gain, to identify relationships and optimize management practices.

- Improved Decision-Making: Integrated data provides a more complete picture of farm operations, enabling farmers to make more informed decisions.

- Enhanced Efficiency: Integration streamlines data management and analysis, saving time and resources.

- Example: A poultry farm in France integrated its temperature monitoring system with its feeding system. By analyzing the correlation between temperature, feed consumption, and bird growth rates, they were able to optimize their feeding schedules and reduce feed waste. This led to a 2% increase in average bird weight at harvest.

The Role of Litter Management

Effective litter management is a critical, often underestimated, component of temperature regulation within a poultry house. Litter acts as a thermal buffer, influencing both heating and cooling efficiency. Its condition directly impacts the birds’ comfort, health, and ultimately, the overall productivity of the flock. Proper litter management helps to maintain optimal environmental conditions, reducing the energy required for heating and cooling and mitigating the risk of diseases associated with poor air quality and moisture levels.

Litter’s Impact on Temperature and Humidity

Litter depth and composition significantly affect the temperature and humidity within a poultry house. The type of litter, its depth, and its moisture content all contribute to the thermal environment experienced by the birds.* Litter Depth: The depth of the litter impacts its insulating properties. Deeper litter provides better insulation, reducing heat loss in cold weather and moderating temperature fluctuations.

However, excessively deep litter can increase the potential for moisture buildup, leading to higher humidity levels and potentially poor air quality.* Litter Composition: The materials used for litter also play a role. Common litter materials include wood shavings, rice hulls, and straw. Each material has different insulating properties and moisture absorption capabilities. For example, wood shavings generally offer good insulation, while rice hulls can be more effective at absorbing moisture.* Moisture Content: Litter moisture content directly influences the relative humidity within the poultry house.

High moisture levels can increase humidity, making the environment feel colder in winter and hotter in summer. Excess moisture also promotes the growth of harmful bacteria and ammonia production, which can negatively impact bird health. Conversely, excessively dry litter can lead to dust problems, potentially affecting the birds’ respiratory systems.

Best Practices for Optimal Litter Conditions

Maintaining optimal litter conditions involves several management practices aimed at balancing temperature, humidity, and air quality. These practices are essential for creating a healthy environment for the birds and maximizing the efficiency of the poultry house’s climate control systems.* Choosing the Right Litter Material: Select litter materials based on their availability, cost, and suitability for the specific poultry operation. Consider factors such as absorbency, insulating properties, and potential for dust production.

Wood shavings and rice hulls are widely used due to their good performance characteristics.* Managing Litter Depth: The ideal litter depth varies depending on the age of the birds, the season, and the type of litter material used. Generally, a starting depth of 3-4 inches is recommended for broilers, with adjustments made as needed. Observe the litter condition and adjust the depth to maintain a balance between insulation and moisture control.* Monitoring Moisture Levels: Regularly monitor litter moisture levels, ideally with a moisture meter.

The optimal moisture content typically ranges between 25% and 35%. High moisture levels require intervention.* Ventilation and Airflow: Adequate ventilation is critical for removing excess moisture and ammonia from the litter. Ensure that the ventilation system is functioning correctly and provides sufficient airflow throughout the house. The goal is to maintain a balance between removing moisture and conserving heat during colder months.* Turning and Aerating Litter: Turning or aerating the litter can help to break up compacted areas, improve air circulation, and promote drying.

This can be particularly beneficial in areas with high moisture concentration.* Preventing Water Leaks: Regularly inspect and repair any water leaks in the house, including those from drinkers and water lines. Leaks contribute significantly to litter moisture.* Controlling Ammonia Levels: Ammonia is a byproduct of the breakdown of uric acid in the litter. High ammonia levels are harmful to the birds’ respiratory systems.

Monitor ammonia levels regularly and take corrective actions, such as increasing ventilation or adding litter amendments, if levels become excessive.* Litter Amendments: Certain litter amendments, such as hydrated lime or sodium bisulfate, can be used to reduce moisture and ammonia levels. However, use these amendments cautiously and follow the manufacturer’s instructions.* Removing Caked Litter: Remove caked or wet litter promptly.

Caked litter can create hot spots, harbor pathogens, and exacerbate moisture problems. Spot clean wet areas as needed to maintain overall litter quality.* Example: Assessing Litter Conditions: A poultry farmer in Arkansas noticed an increase in respiratory problems in his broiler flock during a particularly humid spring. Upon inspection, he found that the litter moisture content was exceeding 40% in several areas, despite a well-functioning ventilation system.

By implementing a plan that included spot cleaning, adjusting the ventilation settings, and adding a litter amendment, he successfully lowered the moisture levels and improved the flock’s health and performance. This example illustrates the direct impact of litter management on bird health and productivity.

Water and Feeding Strategies

Water and feed are critical components in poultry management, especially when dealing with temperature regulation. Both directly impact a bird’s ability to cope with heat stress. Strategic management of these resources is essential for maintaining poultry health, performance, and profitability during hot weather conditions.

Water Availability and its Influence

Water availability significantly influences a poultry’s ability to thermoregulate. Dehydration can quickly exacerbate heat stress, leading to reduced feed intake, decreased growth rates, and even mortality.

- Water facilitates evaporative cooling: Birds, lacking sweat glands, rely on panting and evaporative cooling from their respiratory tracts. This process requires significant water.

- Water intake increases during heat stress: Birds instinctively increase their water consumption to facilitate evaporative cooling. In hot weather, water intake can double or even triple compared to cooler conditions.

- Reduced water intake leads to heat stress: When water availability is limited or compromised, birds cannot effectively cool themselves, leading to a rapid increase in body temperature and the onset of heat stress.

- Water quality matters: Water quality impacts consumption. Poor water quality (e.g., high mineral content, contamination) can reduce water intake, worsening heat stress.

Modifying Feeding Schedules and Feed Types

Modifying feeding schedules and feed types are crucial strategies for mitigating heat stress in poultry. Changes in these areas can reduce metabolic heat production and improve overall bird well-being.

- Feeding during cooler parts of the day: Adjusting the feeding schedule to coincide with the coolest periods of the day (early morning and late evening) can reduce the metabolic heat load on the birds during the hottest hours.

- Using feeds with lower heat increment: The heat increment of feeding (HIF) refers to the increase in heat production following the ingestion and digestion of food. Formulating diets with lower HIF can help reduce the bird’s overall heat load.

- Reducing protein levels: Excessive protein intake increases metabolic heat production. Reducing dietary protein, while still meeting the birds’ amino acid requirements, can lessen the heat load. However, this must be carefully managed to avoid impacting performance.

- Increasing dietary fat content: Replacing some carbohydrates with fat can help reduce the HIF. Fat digestion produces less heat compared to carbohydrates. This approach should be implemented with caution, considering potential impacts on feed palatability and gut health.

- Providing electrolytes: Adding electrolytes to the feed or water can help birds maintain electrolyte balance, which is often disrupted during heat stress due to increased panting and water loss.

Ensuring Adequate Water Intake

Ensuring adequate water intake is paramount during hot weather. Several strategies can be implemented to guarantee that birds have access to sufficient, clean water.

- Increasing the number of drinkers: Providing more drinkers or increasing the number of drinking points can help ensure all birds have easy access to water.

- Checking and maintaining water lines: Regular inspection and maintenance of water lines are essential to prevent leaks, blockages, and ensure adequate water flow.

- Using nipple drinkers or cup drinkers: These systems can reduce water wastage and maintain water quality better than trough drinkers.